Thoughts On Barrel Twist, Bullet Weight And Precision

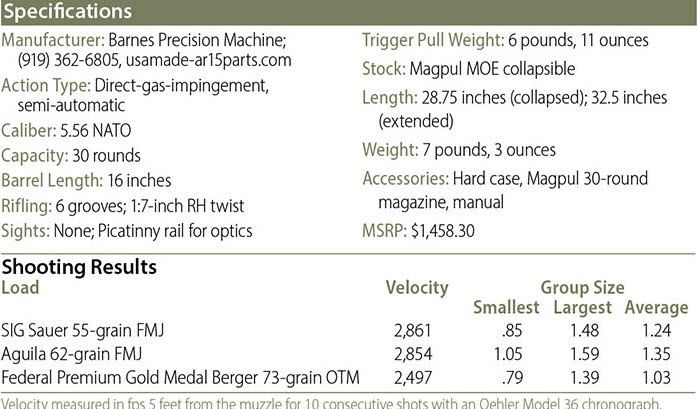

BY Herschel SmithShooting Illustrated had an assessment of the Barnes Precision Carbine. It seems a nice enough gun, although for the price you’re getting into BCM and Rock River Arms prices. I do like the looks of the hand guard, though. But what caught my eye was this chart.

I find this fascinating. I’m a wonk, I admit. But even if you don’t find it as interesting as I do, I’d request that you [a] see this first and foremost as a fishing expedition, not a tutorial (because that’s not my job), and [b] keep track of similar data and send to me as you run across it.

So here’s my specific interest. Technically, MOA is a measure of precision, not accuracy. Accuracy can be modified based on sight (or optic) adjustments. If you don’t understand the difference between accuracy and precision, without going through the mathematics of the Central Limit Theorem, you can see this article. So now you’ll understand why I am using the term precision for this information.

The precision is lower for the 62 grain bullets than for 55 grain or 73 grain. It would have been nice to see additional testing with Sierra MatchKing 77 grain OTM. The difference above is nontrivial.

We saw in a previous post (not because I knew this information, but because I know how to find this information) that when the Army tested the M855A1 round, they were using accurized 1:8 twist barrels, not 1:7 twist as per MilSpec. They got worse precision with the new ammunition with 1:7 twist barrels. The M856 tracer round is 63.7 grains, and the Army had to show that the barrel could stabilize the round in order to justify the new bullet.

A twist rate that is too high can over-stabilize bullets, leading to “keyholing.” We know that, and so it’s important not to overdo barrel twist. It is fairly standard knowledge that use of the 1:7 twist leads to slightly less precision for the 55 grain, and maybe for the 62 grain green tip. But it manages to stabilize the heavier rounds, including the rounds that are apparently in current use within SpecOps.

This stabilization is necessary because of changes made to the service rifle. The original M-16 had a much milder twist rate than does the shorter barrels in use today. The shorter barrels are a direct result of trouble getting into and out of vehicles for dismounted operations, going through buildings and around walls, and the general requirements of MOUT. In order to make the ammunition work for these shorter barrels, the engineers had to monkey around with twist.

Now I’m to my main point. I take interest in the fact that the precision is lower for the medium weight bullets. I’ll stipulate that the variables are many, including perhaps the most important one, barrel harmonics. I’d love to talk to some of the original engineers and test shooters for the newest Army round, but it’s likely that I’d never get the truth.

But what I can do is compile data of my own. I’m wondering if this behavior stands up with other twist rates? I’m also interested in whether barrel length plays a role. Why did the precision decrease with medium weight bullets, and recover at the lower and higher ends?

At any rate, if you run across any data for 1:9 twist, 1:8 twist, or any more data on 1:7 twist, using different bullet weights, I’d be very interested to learn the precision of the groups and plot for future reference.

Thanks in advance.

On December 3, 2019 at 8:00 pm, Bill Sullivan said:

I have a Stag-15 with 1/9″ twist. XM-193 and XM-855 only group about 3″-4″ at 100 yards. Federal ammo.

Privi Partizan 75 grain match ammo gives sub-moa, consistantly.

On December 3, 2019 at 9:27 pm, mobius said:

https://groups.yahoo.com/neo/groups/handloading/info

On December 3, 2019 at 10:22 pm, Georgiaboy61 said:

@Herschel

“A twist rate that is too high can over-stabilize bullets, leading to “keyholing.” We know that, and so it’s important not to overdo barrel twist. It is fairly standard knowledge that use of the 1:7 twist leads to slightly less precision for the 55 grain, and maybe for the 62 grain green tip. But it manages to stabilize the heavier rounds, including the rounds that are apparently in current use within SpecOps.”

Key-holing typically results from lack of spin stablization, not an excess of it. Conversely, the phenomenon of over-spinning a projectile is real, but less common today that it used to be, thanks to improved materials and manufacturing processes by bullet makers. Perhaps you or some of your readers have seen a light-weight varmint bullet disintegrate from being shot out of a barrel using too-rapid a twist.

A twist rate which is borderline too slow, i.e., a 1:9 for firing a .224-caliber 75-grain BTHP projectile, can sometimes be compensated for with a higher muzzle velocity and/or a longer barrel. A 22-inch 1:9 barrel bolt-action rifle may stabilize the projectile whereas a 14.5-inch or 10.5-inch barrel may not.

Projectile weight is not the only factor which determines the correct (ideal) twist rate; projectile length and overall design play large roles, as well as the materials used to make the barrel, how it is finished, as well as the material(s) from which the projectile is made. Brass solids (such as those marketed by Barnes and Hornady) tend to need a faster twist, all other things being equal, than traditional lead-core bullets with gilding metal plating.

Every barrel is unique. Theoretically, a 1:9 barrel ought to be too slow to stabilize a match-grade .224-caliber 75-77-grain projectile, but I have owned barrels in that rate which have done the job – and ones which have not.

Bryan Litz, of Applied Ballistics, is an excellent source for reliable information, careful experimentation, and rigorous analysis about these issues. In addition to being a seasoned competition rifle shooter, he heads “Applied Ballistics,” as well as serves as the chief ballistician for Berger Bullets. Litz is an aeronautical engineer by training. Bryan has an advanced grasp of the mathematics involved, as well as some of the other more-advanced, specialized content. If you don’t know his work, check him out – you’ll be glad you did.

On December 3, 2019 at 10:34 pm, Herschel Smith said:

@Georgiaboy,

See:

https://www.youtube.com/watch?v=SKbbuZDPw80#action=share

Rex explains. 38 seconds in. Overstabilized, the nose of the bullet never turns over to follow the trajectory, leading to keyholing.

On December 3, 2019 at 10:48 pm, BRVTVS said:

@Herschel

The maximum point blank range of the 223 is on the order of 250-300 yards. Assuming the groupings on the chart were generated at 100 yards, I don’t believe the arc of the bullet trajectory would have deviated sufficiently from a straight line for overstabilization to become a significant issue. I think a long range shooting test of ~500 yards would be needed to reveal those sorts of problems.

On December 3, 2019 at 11:25 pm, sobiloff said:

You may be over-extrapolating from this data. Aguila is very mediocre ammo (at best), whereas the Sig and Federal ammo is generally much better quality and more consistent. I’d be more confident in evaluating the effect of the twist rate if you held the other variables more tightly.

Also, I think Rex is exaggerating the effect to make a point. In practice I’ve never seen over stabilization result in obvious keyholes, whereas I have seen reduced consistency and bullets vaporizing in flight.

On December 3, 2019 at 11:39 pm, Herschel Smith said:

@sobiloff,

That thought had occurred to me. Ammunition is a huge variable. And like you, I don’t like Aguila. I really wonder why they used it. PMC, or Winchester, or better yet, Hornady 62 gr., would have been better.

On December 4, 2019 at 12:10 am, Georgiaboy61 said:

@ Herschel

Re: “Rex explains. 38 seconds in. Overstabilized, the nose of the bullet never turns over to follow the trajectory, leading to keyholing.”

Thanks for jarring my memory, you are correct. But so was I, since key-holing is also seen (often at quite close range) when the projectile isn’t spun at high-enough RPMs to attain gyroscopic stability.

On December 4, 2019 at 12:13 am, Herschel Smith said:

@Georgiaboy,

Yes. And I also think that sobiloff made a good point above. I should have looked closer at the ammunition they used for the second row of testing in the table.

Good grief. You’d think Shooting Illustrated would do better than that.

On December 4, 2019 at 3:28 am, Chuck said:

I doubt you’d get accurate or even truthful information – it would be proprietary intellectual property of the competitors – but it might be interesting to build a list of bullet weight, bullet type and twist rate from the rifles on the High Power line at Camp Perry. The same barrel gets used for 200, 300 and 600 yard targets, and whatever is very well stabilized for maximum precision at 600 is also probably very well stabilized for 200 and 300.

On December 4, 2019 at 8:40 am, George said:

Here are two rifles I have and load results for my last time out. 5 shot groups. Sorry I did not use all of the same ammo for the two rifles:

1. Noveske lower with La Rue predator 18″ barrel, 1-8 RH twist:

Federal XM-193 55gr: 1.5 in @100yards

Barnes Precision Match 69 gr OTM : .76 in @100 yds

Federal XM855 62gr: 1.7 in @100 yds

Hornady Black 62gr FMJ: 1.6 in @100 yds

Fiocchi Exacta 223 77gr SMK HPBT: .47@100 yds

2. Noveske Lower with La Rue predator 16″ barrel 1-8 RH twist:

Federal XM 855 62 gr: 2.5 in @100yds

Federal 77 gr SMK: .76 in @100 yds

Federal XM 193 55 gr: 2.9 in @100 yds

Hornady Black 62 Gr FMJ: .70 in@100 yds

Fiocchi Exacta 223 77 gr SMK HPBT: .98in @100 yds

The Barnes 69 gr and the Fiocchi 77 have shot well for me in just about every rifle I have tried them in.

On December 4, 2019 at 10:26 am, Bill Sullivan said:

Stray comparative info: I have a .22-250 target rifle with a 1/14″ twist. It shoots about 1/2″ groups consistently at 100 yards with a 55 grain bullet going out at a chronographed 3100 fps. Mild load out of a 26″ barrel, and used for 4 position matches at 200 yards. But, the velocity is pretty comparable to the 55 grain 5.56mm load out of a 20″ barrel. I have not tried loading any heavy weight bullets out of it, but it would be an interesting experiment.

On December 4, 2019 at 10:41 am, Old Bill said:

The difference in precision is most likely inherent in the bullets in both the M855 (Green Tip) and the Army’s newer M855A1 (Bronze Tip), and for similar reasons. Spin stabilization ASSUMES a center of mass that lies somewhere along the centerline of the projectile. Both the above bullets have formed-in hardened penetrators. Achieving a center of mass ON the centerline with that construction is nearly impossible. This is a known feature of the M855 that is well documented. The M855A1 will suffer from it as well because it is the inevitable result of the design chosen.

“Well, why don’t artillery shells suffer the same problem if it’s so impossible to control?” Balancing a several-pound, 120mm diameter projectile requires less precision than balancing a 0.308″ diameter, 62gn (0.00886 Lb.) rifle bullet.

Twist rate is a tempting thing to look at given the results, but in this case it’s the bullets themselves that tell the tail.

My opinion, and worth everything you paid for it….

On December 4, 2019 at 2:53 pm, Adino said:

Being new to the table, the following suggestion might be old hat and previously rejected, and if so apologies in advance.

I’ve been a Gun Tests (gun-tests.com) customer for a number of years. If data like that submitted for the Barnes Precision Rifle is craved (I crave the same) a subscription may be worth it. I hopped in bed with my last subscription for like $55 for 3 years. And that gets access to the web site with enough data to keep you occupied for some time. In the grand scheme of things, not a lot of money to keep me from considering a bad investment (I am in no way affiliated with Gun Tests, btw, just wanting to share the joy).

I will also echo @ Georgiaboy’s observation about every barrel being different. Nice data for the barrel tested, but who provided the barrel? Manufacturers providing guns for testing may yield cherry picked beauties. What about a dude like me that grabs one off a shelf in the middle of flyover? That’s one of the reasons I like Gun Tests. They grab guns and ammo and accoutrements from a shelf, just like a nobody like me, to run it for fun.

The base metal the barrel is comprised of, and it’s homogeneity, are critical for button rifled barrels.

Hammer forged barrels can enhance homogeneity between barrels in the batch (and between batches) by overcoming the metallic blank variation with its work hardening of the metal around the mandrel, making comparison of barrels more applicable than those between button rifled barrels, which depend on the ‘touch’ of the machinist and consistency of a metal blank, more pertinent. That doesn’t make them ‘better’.

imho, the diminished inconsistency between barrels pounded onto a mandrel is desirable, so that one barrel ‘acts’ the same under similar conditions without regard to the rest of the gun the barrel is a part of, but would say a well made button rifled barrel can stand up with a talented practitioner at the fire control.

The above equivocation, however, doesn’t make a ‘buy’ decision based on manufacturer easy for me as the lower tier shooter wanting to get the best ‘bang for the buck’ :), which is the whole point of the conversation and data request.

There is variation in ammo as well. Who provided that for testing? That can be overcome with the statistics of testing more rounds (and who doesn’t want to be part of that experiment) but the cherry picking variable sticks it’s head under that tent too!

Proper comparison entails limiting variables. As many as possible.

That will never make up for time and training, and weapon and ammo selection, (manufacturer and batch specific – thanks to George for the Fiocchi and Barnes ammo comparison) differences. But it does get you in the ballprak.

One always wants to know if you are swinging a Louisville Slugger or a knock off before spending what that bat costs.

So many variables.

No wonder it’s an art all around.

On December 5, 2019 at 6:07 pm, Georgiaboy61 said:

@ Herschel

Further ideas/observations on twist rate and stability….

Vis-a-vis our earlier discussion of key-holing, an additional observation is that the effect is often observed on paper targets placed within the transsonic or subsonic zone of that particular cartridge/projectile combination.

In an AO (area of operation) where a typical .308 Winchester load of a Sierra 168-grain Match King BTHP Match can be expected to become transsonic around 950 yards, the projectile is approaching the lower bound of supersonic flight, i.e. @ sea level = 1120 fps. Not only has the shot dumped considerable velocity, it is also spinning a good deal less-rapidly, also degrading gyroscopic stability.

Years ago, it was common for M14/M1A service rifle competitors to use 168-grain BTHPs at 600 yards, with great success out of those 22-inch barrels. However, many of those same competitors found that the 168-grain BTHPs often key-holed at 1000 yards, depending on local environmental conditions of course.

The 168-grain match bullets were entering transsonic flight too close to 1,000 yards, leading to inconsistent performance. Since the typical match-grade bullet is nose-light, and has its center of gravity aft of its high-pressure zone, when the velocity and spin of the projectile have degraded enough, pretty much the first thing the bullet wants to do is “swap ends,” i.e., reorient itself heaviest end forward.

Like a tightly-thrown spiral in football when the QB throws a “long bomb,” that spin will keep the long axis of the football oriented properly along its intended line of flight, but as soon as its velocity and spin degrade sufficiently, the ball will begin the yaw and flutter, and may even start to tumble end-over-end. The same effect, approximately speaking, occurs with bullets – and when it does, key-holing is often observed on the target paper. An irregularly shaped hole resembling a key-hole and not the normal circular or near-circular hole observed from a well-stablized shot.

Rex, being an expert LR/ELR marksman, is undoubtedly familiar with this effect, as are many of your readers.

In recent years, researchers and technicians of various kinds have made significant advances in bullet transsonic stability, and have created designs which retain their stability into and through the transsonic zone and at sub-sonic velocities. Further, bullet designs with extremely high ballistic coefficients are now available, from Hornady, Berger, Sierra, Barnes, and a host of other manufacturers, to say nothing of expensive custom-turned ammo produced on lathes to exacting standards.

These advances had partly to do with the dramatic – even prodigious – gains made in successful ELR shooting and sniping over the last two decades. It wasn’t all that long ago that anyone (civilian or military) shooting out to a mile was cutting edge, but today, U.S.-NATO personnel in Afghanistan and Iraq have successfully engaged “tangos” (enemy targets) at ranges in excess of two miles distance. On the civilian competitor side, there is the “King of the Two Mile” ELR competition held out west each year.

On December 5, 2019 at 7:55 pm, Herschel Smith said:

https://www.youtube.com/watch?v=Wvu2d8Kx0es